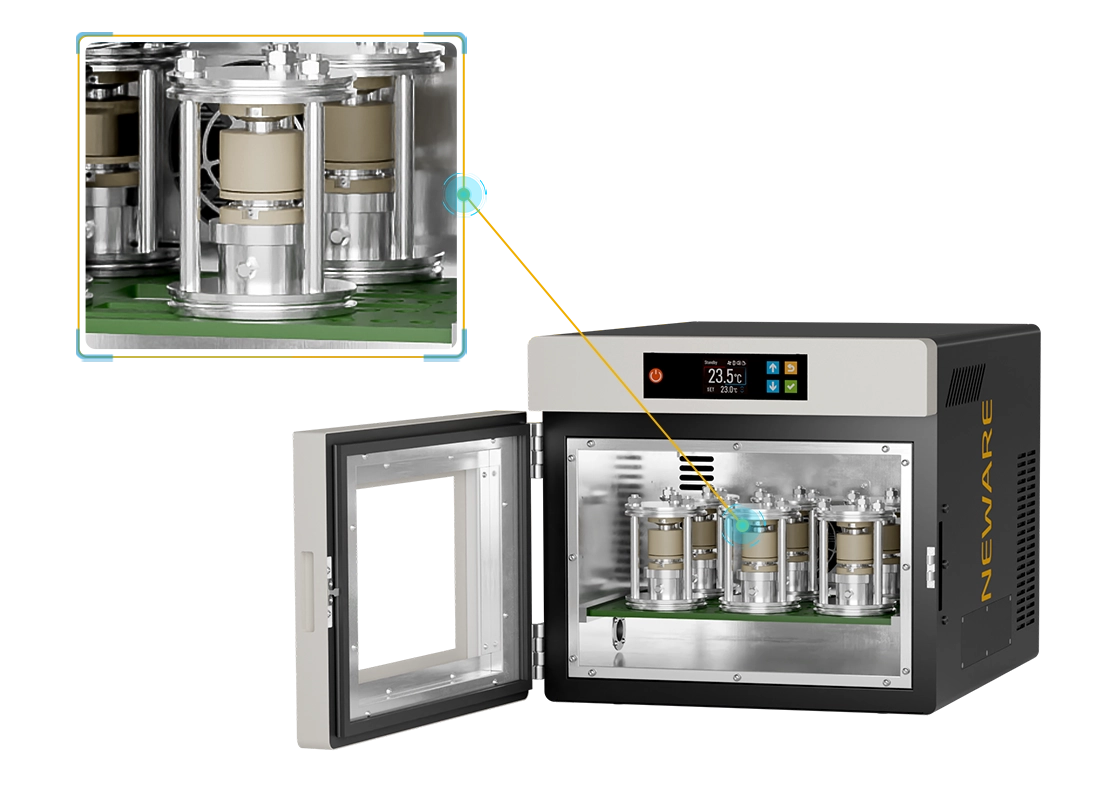

● Simple structure, easy to operate, can be used in a glove box.

● Made of high mechanical strength and corrosion-resistant PEEK material to ensure the durability and chemical stability of the mold.

● Good sealing performance, compatible with pressure sensors.